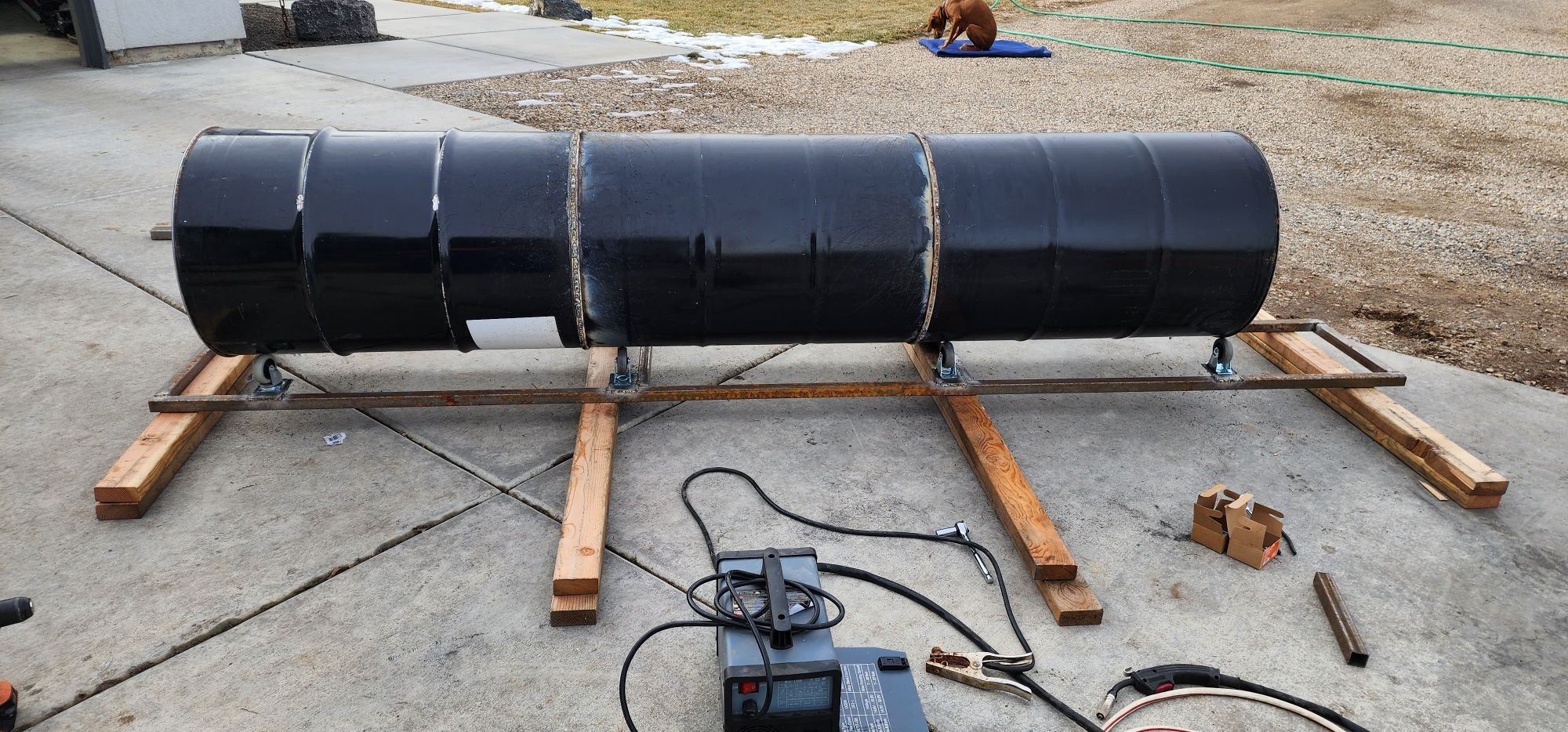

Big time trommel

Hey everyone on the interwebs.

I have been involved in bonsai for some time now. Every year I become more involved with other practitioners, artists, and collectors. With these engagements, I have been fortunate to glean information and experience from these folks. With these learnings, I have recognized the need to improve processes that will allow me to enjoy this hobby/lifestyle longer into my more veteran years.

With that being said, this build write-up is geared at showing you another tool I have created.

The dilemma - I need an easier way to sort out particle sizes in my planting medium. What I mean by that is, when I collect grit, pumice, or garden mixes I currently have to hand-sift the components. If this material was just for me, that wouldn’t be an issue, but typically a couple of times per year I end up sifting materials for myself our various club members, or customers. I am happy to do this and enjoy the work, but this is tiring and long term I need an easier way to perform this work. Hence the build you see here.

So far I have built three different methods for sifting,

Version 1 was a wooden frame with hardware cloth attached in two different sizes (1/8 + 1/4 in.) This frame was roughly 3ft long x 18in wide x 4in deep. The shaker was placed on casters and installed inside of another frame just a bit longer and wider than the shaker frame. This allowed the shaker to move forward and backward and gravity draws the particles down through the screen. I placed the frames on top of cattle troughs making the collection of the material easy. I could sit on the ground and move the trays to complete the collection of materials. When the troughs were full, I used a shovel to place the desired particles into 5-gal buckets for use later.

Version 2 was a similar design in shaker size and function. I improved the design by standing the shaker at countertop height (well, slightly taller). I built a set of larger wooden frames raising the trays up. I placed the cattle troughs below and captured the particles in the same fashion as above. This allowed me to shake a bit more vigorously and also allowed the medium being captured to fill the trough to the top. Also, this was easier on my back and knees allowing me to stand while sifting.

Each year of sifting and the growing requests from others in the hobby has increased the volume of sifting, the amount of work, and also the amount of time required to gather what is needed for the demand. Again, I am not complaining, I’m being honest about how to scale the work, effort, and ability to provide this service with longevity.

This brings me to the version you see Version 3. before I began, I did some serious research into a cost-effective design with the focus being on function, durability, and ease of operation.

Design - This needed to be large enough to handle lava rock (cinder), decomposed granite, various organics (bark), Akadama, and pumice. I also want the trommel to be at a comfortable height for loading, gathering, and moving it around.

Function - The functionality of this device has to be intuitive, i.e. low training barrier. It needs to be easy to set up and dismantle and it needs to separate particles into sizes I can utilize.

Durability - I want the trommel to be made out of metal - ideally steel. This is heavy but it will stand up to the abuse it will take. I can also repair it quite easily if I had issues. For the drum, I used reclaimed 55-gal barrels (brake cleaner). I used brake cleaner drums because they didn’t have any residue and were really clean before construction began. To support the drum, I used heavy-duty casters mounted to the base frame. The drum sits on these casters allowing the rotation of the drum to be very smooth. I cut panels out of the drums that allows the screens to come in contact with the medium being filtered. Once all the drums had the panels removed, I wrapped the drums with galvanized steel hardware cloth as the sifting material similar to the above methods in rev 1 & 2.

Operation - The trommel is built on a slight downward angle. The medium is added to the top of drum with 1/8th screen installed. The material gently tumbles down the length of the inside of the drum with a simple rotational pull in either a clockwise or counterclockwise motion. The drums have handles installed making the effort needed to rotate the drum assembly easy and smooth. The top drum screen filters out the fines and dust, falling to the ground. The second and third drum are outfitted with 1/4 in screen which is captured in either a trap or cattle trough. The reason for two sections of 1/4 screen is that this material size is the most needed size for “most” potting situations. All of the larger sizes +1/4 in size drop out of the end of the drum and can be captured in a bucket or sifter for additional sizes as needed. Operation is simple, requiring a pull or push from the person using the drum. I intend to install a small electric motor for myself. Then I can operate this by myself with a battery or connected to my pickup.

Additional thoughts - The trommel frame is built out of square tube steel and has supporting bracing at both ends and also vertically. This keeps the trommel from wanting to topple in the lateral direction when applying a rotational force. And the vertical bracing supports the load in the center of the drums at the welding joints. This Insures smooth operation removing any sagging in the structure.

Thanks for sticking around!

Jon